Tel: +86-755-2302 5312

Fax: +86-755-2302 5312-8006

Email: sales@graperain.com

Address: Room 1801-1805, Huafeng International Business Building, No. 4018 Bao'an Avenue, Bao'an District, Shenzhen

Post Code: 518000 Skype:

Skype:

Embedded Custom Service

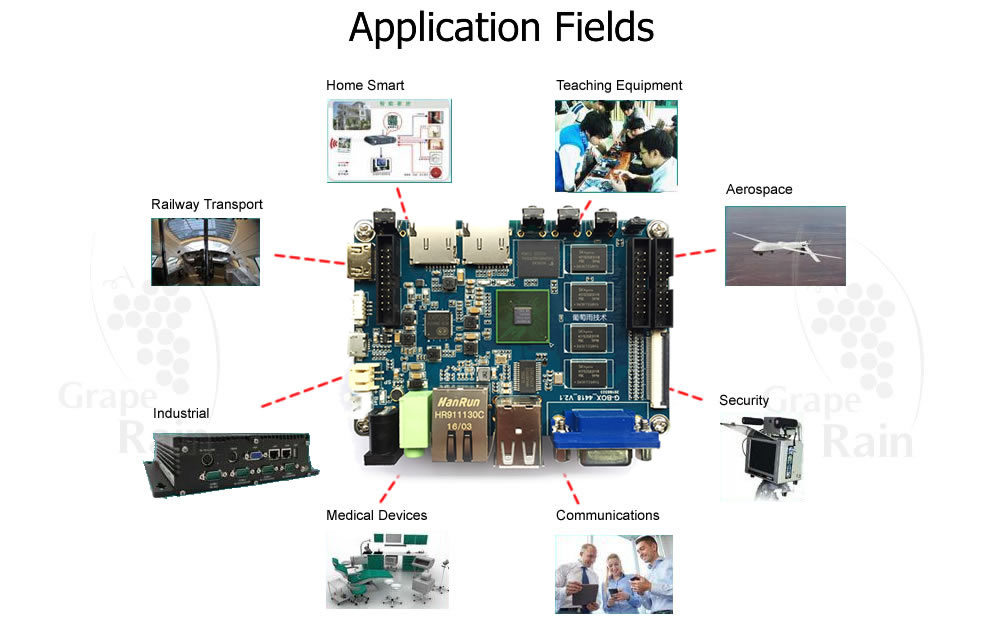

ARM Customized Solution Range:Samsung Android/Linux Solution, Snapdagon MSM 8916 Android Solution, RK3288/RK3399 Solution

Our Services- Embedded hardware design

- Schematic Design

- Schematic Review

- PCB Layout

- Schematic Review

- System Customization

- SDK Customization

- Kernel Tailoring

- Driver Development

- Firmware / System Upgrade

- Kernel Tailoring

- Commissioning Tests

- Provide Development environment

- Build Development environment

- Customer prototype debugging

- Testing tools

- Build Development environment

- Manufacturing Process

- Batch Programming

- Trial Production guide

- The First Production

- Problem Analysis and Solving

- Trial Production guide

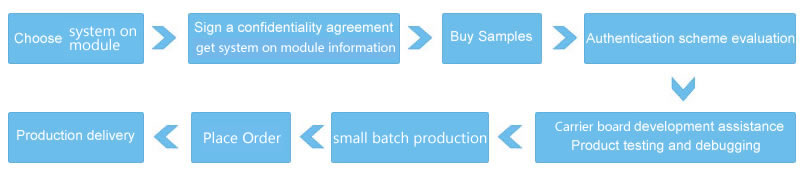

- System on Module Cooperation Way

- Customers: customers should have hardware and software design R&D capability, upper application development ability.

- Features: simple, high-efficiency, great flexibility, users can design and produce themselves.

- Cooperation procedure:

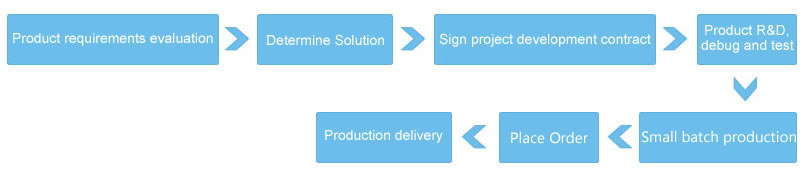

- Industrial Customized Cooperation Way

- Customers: with industrial-strength or resources in application development.

- Features: professional, stable, no burden on customers. Based on product functions, mold and other characteristics, we can help design product that can be manufactured in mass production directly.

- Cooperation procedure:

Embedded Hardware Design and Development is an integral part of product development. These services are intended to complement the embedded systems design and software design and development services offered. This hardware design is for microcontrollers and microprocessors or smaller FPGA systems. The hardware design, both mechanical and electronics, is done in parallel with software development..

Embedded System Hardware Design and Development Overview The hardware design process involves both mechanical design and electronics design. The basic process starts with conceptual design during the embedded systems design and requirements specification phase. In this activity the requirements and conceptual design is explored further to ensure suitability for the final implementation.

Hardware Design Process

The hardware design process is as follows:

- Node Hardware Requirements specirfication

- Detailed node architecture and design for electronics in parallel with detailed mechanical design and packaging concept and initial prototypes

- Part selection, schematic capture, printed circuit board design and layout in parallel with mechanical prototype refinement

- Prototype assembly and further mechanical refinement

- Prototype bring-up, design verification and testing

- Documentation and support in parallel with automated manufacturing testing and end of line testing.

Mechanical Design

The next critical element in the mechanical design portion of the embedded hardware design and development is to converge on a single design that meets all of the overall criteria. By converging on a single approach, the effort of perfecting the design can be focused on a single design. If there is risk issues associated with the design, these risk items should be resolved early through research and experimentation.

An example of risk reduction might involve a prototype of the case made with a 3D printer, which might then be stuffed with a dummy circuit board wih an attached speaker and wires which are put through a hole in the case. The unit could then be closed and the speaker driven by an external source to test the acoustic properties. This would just reduce the risk because the final case would be different, but it could provide a good measure of resonance problems and other related issues.

The electrical and electronics portion of the design must occur in parallel. Both proceed to completion in parallel. Issues in either the electrical or physical design can force rework in the other. This is why it is necessary to eliminate risks early as it will minimize the overall cost.

Electronics Design

From the specifications, the electronics design is undertaken using developers which are as experienced as the project is difficult. Often for simple single board microcontroller designs, more junior designers are used with an experienced supervisor. In the case of more complex designs with multiple add on boards, a better more experienced designer is required. Generally though, microcontroller based designs and small microprocessor designs or simpler FPGA designs do not require the best and most experienced designers.

As in the mechanical design case, risk reduction at early stages is a priority. An example of risk reduction could involve a trial hardware layout of the components on the circuit board to make sure that they will all fit. The goal might be to make a 4 layer board, maximum to keep within the BOM cost range. The trial layout would determine the physical layout, confirm that the heat could be disapated and all the components could fit comfortably using the preferred packaging approach (ie SMT, BGA, ...) and that the other constraints were met.

On the Division and Cooperation of Embedded Product Design

A complete embedded product design generally involves a lot of work, including hardware design, system BSP package migration, driver porting, the middle of the protocol layer and components, GUI graphical interface and terminal applications.

So many links if all the independent completion of a company, is bound to time, R & D team, the cost of making a huge investment, which is clearly the market and product requirements for the rapid listing and cost-effective contradiction.

So how can the whole product meet the market requirements of these two points? Senior embedded technology manager Yang Kun according to his years of experience in the embedded field of work put forward personal views, he believes that social division of labor brought about tremendous productivity, same as embedded product design can not be done independently by a company. And a good embedded products in the ecological chain needs of other experienced, professional division of labor to complete the joint work. At present, many large companies exist because they are in a field of professional rather than omnipotent, so now, a complete embedded product design work is often divided into several parts to achieve division of labor.

User Application and GUI Graphical Interface

Application is the most extensive, the most flexible concept, all walks of life have their own different characteristics and requirements, which requires application developers on the corresponding industry in-depth understanding. This part of the implementation of the project is often the initiator of demand and product integration side. They often have the core technology of an application and have their own industry customer base, but they have no relevant experience in hardware design and platform design, or do not want to invest too much in this area for other reasons. Most of the embedded operating system GUI graphical interface is not a necessary component of the operating system but as the upper application graphics library by the user to select and transplant, such as Linux operating system users can choose QT or GTK as its graphics library.

Intermediate Protocol Layers and Components

This part of the system generally includes some basic applications, the protocol stack and audio and video decoders such as the composition of the middle components. This type of professionalism is often relatively strong, and its related technology in the hands of some professional commercial companies or by the open source organization for free distribution. For commercial companies to provide the technology often need to obtain the right to use the right to pay, or paid a custom way to obtain these commercial companies and organizations, we generally call it a third party.

Hardware Design, System BSP Package Migration, Driver Transplantation and so onCPU (CPU), is the core of the digital automation era, and embedded products is to achieve the digital and automated equipment, we can see the importance of CPU for embedded products. The initiator of the project requirements and the integrators of the products often only know how to develop user applications, but they do not know how the complex CPUs support their programs, which requires others - the embedded hardware platform vendors.

Embedded hardware platform provider is to complete this third part of the division of labor, this part of the work is the basis of the entire product is often said that the bottom of the industry. If the underlying did not do bits, then the reliability of the entire system will be out of the question, and now we are on the third part of the two aspects of understanding the bottom.

Hardware Design

As the CPU running frequency is now higher and higher memory from the lower frequency SDRAM has been rising to high-speed DDR3. This makes the design can no longer single-chip lumped parameters of the circuit way to achieve, many times must be distributed in the form of parameters to design. Key factors to consider include power integrity, signal integrity, and EMC to ensure that the hardware is designed to operate reliably at high loads. Power supply from the device selection, filtering to the PCB power distribution layer must do a careful analysis and planning. Signal we rise the edge of the signal with the signal frequency to determine whether the signal is a high-speed signal. In dealing with high-speed signal when we pay attention to the signal plane reference plane to ensure that it has a complete loop.

Such as the fiery community boards: evaluation boards based on the Freescale i.MX 6-series processors, and evaluation boards based on the TI AM335X. This board uses a high-end processor such as the Cortex-A8 or Cortex-A9, and the CPU upgrade to upgrade to DDR3 memory to meet higher throughput, hardware upgrades to our design has brought unprecedented Of the challenges. This part of the design we need from the system average, full load and peak power consumption and other aspects to fully consider the power supply load capacity, and from the reference voltage and DDR signals in the PCB signal line alignment of the key signal line impedance, and key signals Such as the length of the traces to ensure that the system will not be in the long-term high-load data throughput operation because some signal quality or timing on the lack of margin caused by system instability. Of course, these design experience is not achieved overnight, is the need for a long time through the combination of project practice and theoretical knowledge accumulated, and this is a company's ability to judge this aspect of the development of one of the standards.

System BSP Package and Driver Migration

First of all, engineers need to understand the structure of the operating system, the operating system under the hardware operation relative to the single-chip commonly known as the bare metal code has several obvious differences. First, the operating system will abstract the operation of the hardware into a specific driver and application layer rather than the direct operation of the bare metal register. Second, the operating system in the driver level will tend to drive a class of thinking by sub-divided into "a class of subsystems for the core code, controller code and device code," so that the driver can be in a different controller And flexible expansion of equipment. Third, due to the existence of multitasking, it must also consider the factors such as concurrency and mutual exclusion. These features make the control of the drive is no longer intuitive.

In the embedded product design division of labor, the project needs the initiator and product integrators tend to complete the user application part, they are a senior expert in various industries, but in hardware design and platform design has no relevant experience and Or because of other reasons do not want to do too much in this regard, often they will find a hardware platform provider to provide technical support in this area. Hardware platform vendors to complete the division of labor in the hardware design, system BSP package migration, driver porting, due to hardware design, system BSP package migration, drive transplant are closely linked, requires the same vendor to complete, which requires manufacturers have a strong R & D technical team , The other side of the product integration is often the hardware platform for their needs and other special requirements for the size of the function, which also requires embedded hardware platform providers have a dedicated service team to support customized services. In China, ARM-based hardware platform vendors, few meet the above requirements at the same time, but also supply a wide range of types of processor hardware platform, which, Beibei Te has been in this area more than 14 years of development experience, and And Freescale, TI, Atmel, ARM, ST and other world-renowned chip manufacturers to reach a strategic partner for many embedded products manufacturers to provide hardware platforms and customized service solutions. In addition, if the product of the integrated side of the audio and video codecs and other professional are often relatively strong demand, you also need to seek the help of third parties.

Tel: +86-755-2302 5312

Fax: +86-755-2302 5312-8006

Email: sales@graperain.com

Post Code: 518000

Address: Room 1801-1805, Huafeng International Business Building, No. 4018 Bao'an Avenue, Bao'an District, Shenzhen

Open Hours:9:00 am to 18:00 pm on Monday Tuesday Wednesday Thursday Friday

Copyright © Shenzhen Graperain Technology Co., Ltd. All rights reserved.